15 Layers Hot Press Machine-manufacture,factory,supplier from China

(Total 24 Products for 15 Layers Hot Press Machine)

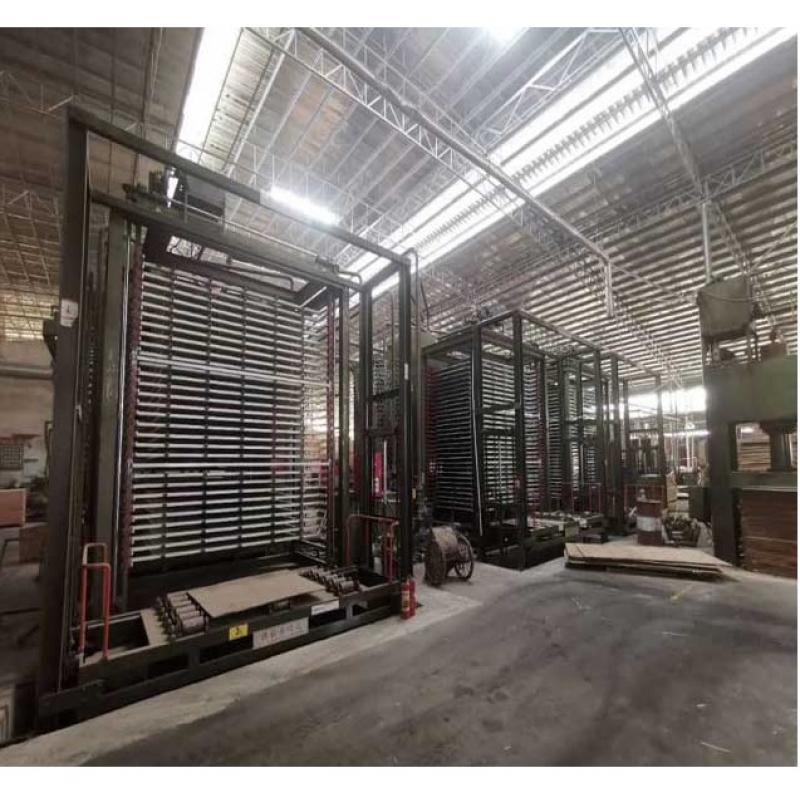

Hydraulic Hot Roller Press MachinePlywood hot press machine is used for the final formulation of plywood, it is the most important machine in plywood production. Hot press machine is one of the most important machines in plywood production.

Связаться сейчас

15 Layers Industrial Wood Machine Hot Press MachinePlywood hot press system can press veneers together with excessive temperature.that's used in furniture and synthetic board secondary operation. guide and automated controls make the hydraulic press quicker, greater precise, and greater convenient for global customers to apply.our warm press is ready with a microcomputer manage device for each guide and automated manipulate.

Связаться сейчас

Woodworking Hot Press Machine For PlywoodPlywood hot press machine is used for the final formulation of plywood, it is the most important machine in plywood production. Hot press machine is one of the most important machines in plywood production.

Связаться сейчас

Hydraulic Veneer Hot Press Machine For PlywoodHot press machine is one of the most important machines in plywood production. It determines production efficiency and the quality of final products.

Связаться сейчас

Automatic Hot Roller Press Machine For LaminatesPlywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation. Manual and automatic controls make the hydraulic press faster, more precise, and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.

Связаться сейчас

Wood Laminate Veneer Hot Press MachinePlywood Hot press machine is one of the most important machines in plywood production.It determines production efficiency and the quality of final products.Hot pressing system, heating system,heat conduction system,low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts,wide range of process parameters adjustment control process,reasonable design to meet various plywood production process requirements. Product parametersTotal pressure500tonsBoard feeding directionFrom the long sidePressure0-25mpaHot P

Связаться сейчас

Plywood Hydraulic Hot Press Machinery Plywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation. Manual and automatic controls make the hydraulic press faster, more precise, and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.

Связаться сейчас

Wood Laminate Veneer Hot Press MachinePlywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation.Manual and automatic controls make the hydraulic press faster,more precise,and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.With a simple push of a button you can control a whole set of processes including pressing plate ascending,closing, pressure adding, pressure maintaining,timing and pressing plate descendin

Связаться сейчас

Wood Laminate Hot Press Machine For PlywoodPlywood hot press machine is used for the final formulation of plywood,it's most the maximum critical machine in plywood production.hot press machine is one of the maximum important machines in plywood production.it determines production efficiency and the nice of final merchandise.Hot pressing system,heating system,heat conduction system,low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts.extensive range of procedure parameters adjustment control system,affordable design to fulfill diverse pl

Связаться сейчас

Multilayers Hot Press Wood MachinePlywood hot press machine is used for the final formulation of plywood,it is the most important machine in plywood production.Hot press machine is one of the most important machines in plywood production.It determines production efficiency and the quality of final products.Hot pressing system,heating system,heat conduction system,low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts,wide range of process parameters adjustment control process,reasonable design to meet various plywood production process requir

Связаться сейчас

Automatic Hot Press Woodworking Machine for VeneerPlywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation. Manual and automatic controls make the hydraulic press faster, more precise, and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.

Связаться сейчас

Hot Pressing Laminating Press Machine For WoodPlywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation. Manual and automatic controls make the hydraulic press faster, more precise, and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.

Связаться сейчас

Roller Veneer Hot Press Dryer MachineRoller Veneer Drying Machine is available in different models as per the production requirement by addition & deduction of different section or decks. The wood core veneer dryer machine adopts a number of high-tech and advanced electronic control technology, so it has the characteristics of high efficiency, energy saving and good dry quality. Veneer drying machine is suitable for peeling core of drying.

Связаться сейчас

Industrial Hot Press Machine ProductsPlywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation.Manual and automatic controls make the hydraulic press faster,more precise,and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.With a simple push of a button you can control a whole set of processes including pressing plate ascending,closing,pressure adding,pressure maintaining,timing and pressing plate descending.&

Связаться сейчас

Wood Laminate Hot Press Woodworking MachinePlywood hot press machine can press veneers together with high temperature.Which is used in furniture and artificial board secondary operation. Manual and automatic controls make the hydraulic press faster, more precise, and more convenient for international customers to use.Our hot press is equipped with a microcomputer control system for both manual and automatic control.

Связаться сейчас

Hydraulic Hot Press Machine For PlywoodPlywood hot press machine is used for the final formulation of plywood,it is the most important machine in plywood production.Hot press machine is one of the most important machines in plywood production.It determines production efficiency and the quality of final products.Hot pressing system,heating system,heat conduction system,low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts,wide range of process parameters adjustment control process,reasonable design to meet various plywood production process r

Связаться сейчас

Wood Plywood Cold Press MachineThe hydraulic press applied to plywood is also called plywood pre-press and plywood cold press. The cold press is also a kind of plywood machine. It is mechanical equipment to shorten the hot pressing cycle and improve the quality of the board. The cold press is a pressure machine. The cold press machine mainly performs a short-time cold press on the veneer after the glue-coated assembly blank, so that it is initially formed, and then sent to the hot press for the process of hot pressing and gluing.

Связаться сейчас

Plywood Wood Cold Press Laminate MachineThe cold press is also a kind of plywood machine. It is mechanical equipment to shorten the hot pressing cycle and improve the quality of the board. The cold press is a pressure machine. The cold press machine mainly performs a short-time cold press on the veneer after the glue-coated assembly blank, so that it is initially formed, and then sent to the hot press for the process of hot pressing and gluing. It is an important piece of equipment to improve the quality of plywood, and it is also an mportant link.

Связаться сейчас

Woodworking Hot Press Machine For VeneerOur Hot press machine low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts,wide range of process parameters adjustment control process,reasonable design to meet various plywood production process requirements. Product parametersTotal pressure500tonsBoard feeding directionFrom the long sidePressure0-25mpaHot Press Plate Size2700*1370*40mm double inlet and outletCylinder diameter and strokeΦ360x2, 1050mmFrameBolt connectedLayer number15 layersLayer space70mmhot press plate number16total power20.5kw

Связаться сейчас

Wood Hot Press Machinery PlywoodHot press machine is one of the most important machines in plywood production. It determines production efficiency and the quality of final products.

Связаться сейчас

Woodworking Hot Press Plywood Machine For WoodHot press machine is one of the most important machines in plywood production.It determines production efficiency and the quality of final products.Hot pressing system,heating system,heat conduction system,low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts,wide range of process parameters adjustment control process,reasonable design to meet various plywood production process requirements.Product parametersTotal pressure500tonsBoard feeding directionFrom the long sidePressure0-25mpaHot Press Pl

Связаться сейчас

Automatic Veneer DryerThe drying machine consists of six layers of conveyor rollers, with each roller transporting veneers through upper and lower pressure rollers to ensure obstruction-free veneer conveyance, thus ensuring continuous equipment operation.

Связаться сейчас

Continuous Veneer Hot Press Dryer EmissionsVeneer dryer Machine is one of important auxiliary equipments in large-scale plywood production line, and help you to improve productivity and reduce cost.The moisture in the veneer affects the total drying time. For example, the difference in moisture content of the heartwood of redwood from different logs may be as much as 2 to 1. The wetter heartwood veneer requires significantly longer drying time than drier heartwood of the same species.

Связаться сейчас

Laminate Hot Press Veneer Machine For WoodPlywood hot press machine is used for the final formulation of plywood,it is the most important machine in plywood production.Hot press machine is one of the most important machines in plywood production.It determines production efficiency and the quality of final products.Hot pressing system,heating system,heat conduction system,low heat consumption,meticulous design,uniform heat conduction,high-precision mechanically processed parts,wide range of process parameters adjustment control process,reasonable design to meet various plywood production proces

Связаться сейчас

Relate News

The shipment of veneer roller dryer were loaded into six trucks at our factory. Main components are: Four layers roller dryer, biomass burner, automatic veneer feeder and veneer collection system.

Our customer in Guizhou put into production a 4 deck veneer dryer equipped with 15 tons of biomass burner. In addition to drying the first-level veneer, the customer also used to dry the second-level veneer and the three-level single-level veneer, and the feedback effect was very good.

Industrial knife grinding machine can automatically adjust the grinding parameters according to the material and shape of different knives, and accurately complete the grinding, repair and maintenance of knives.Industrial knife grinding machine are suitable for grinding all kinds of knives, including but not limited to cutting knives, trimming knives, scrapers, milling cutters, turning tools, etc. Whether it is precision cutting, complex-shaped knives, or large-scale tool repairs, knife sharpeners can complete them accurately and quickly.

There are two traditional heat sources for the veneer dryer, namely, steam boiler and thermal oil heater. The advantages using these two heat sources are one machine can provide heat for more than one veneer dryer. Typically, in a large plywood plant, one big capacity steam boiler or thermal oil heater can supply sufficient heat to several veneer dryers, hot press machines, etc. Only one heat source or heat energy center is enough. The disadvantage is the operation cost will be very high like the fuel cost.

The veneer dryer is currently the most commonly used wood drying equipment. It uses a hot air stove for heating, and the fan blows hot air to the plane of the veneer to achieve the effect of drying the veneer. The quality of equipment drying veneer will directly affect the quality of finished products. Therefore, proper maintenance is required during the daily operation of the machine, which can not only ensure the quality of drying, but also properly prolong the service life of the equipment and save production costs.

Dear customers,We have the priviledge to announce that we will have a public holiday" May Day" from April 29 to May 3rd. However, we still have the shipment plan as follows: Fully Automated Wood Veneer Drying Machine with Biomass Burner (15 Tons) and 7 Trucks to Guangdong; Yunnan Yingjiang's Two-deck, 44-Meter Veneer Drying Machine with Thermal Oil Heating and 4 Trucks; andThailand's Two-floor, 48-Meter Wood Veneer Dryer Machine with 6-Ton Burner and 4 x 40-foot Containers.

Birch veneer has a high shrinkage rate after drying because it is made up of thin layers of wood that have been peeled or sliced from the birch log. When the veneer is dried, the moisture is removed from the wood, causing it to shrink in size.There are several factors that can contribute to the high shrinkage rate of birch veneer after drying. One of the main factors is the orientation of the wood fibers. Birch veneer is typically sliced or peeled from the log in a direction that follows the grain of the wood.

Recently, the roller veneer dryer ordered by our Thai customer has been completed and is ready for shipment. During the shipment process, the sales manager carefully checked the various components of the dryer and confirmed the shipment details and subsequent installation plan. The customer highly recognized the quality of the equipment.The roller veneer dryer adopts advanced hot air circulation technology, which can effectively improve drying efficiency and save energy.

1. Heat exchange systemShine heat exchanger adopts step-by-step heat exchange. The specifications of each section of the heat exchanger are different, and the hot air in the heat exchanger can be evenly distributed to the veneer. The moisture content of the dried veneer is uniform, flat, without wrinkles or end ripples, no cracks, and the surface bonding state is good, which fully improves the energy utilization rate and saves unnecessary energy waste.2.

Many people do not know how to maintain the dryer to extend its service life. Let us take you to understand the daily maintenance of the dryer.1. Clean the inside and outside of the dryer regularly to ensure good ventilation and smooth hot air flow.2. Check the connections and components of the electrical system to see if the components are damaged, aged or loose. If necessary, repair or replace the problematic parts.3. Regularly check the fasteners, belts and chains of the drive system, lubricate and replace necessary parts.4.